|

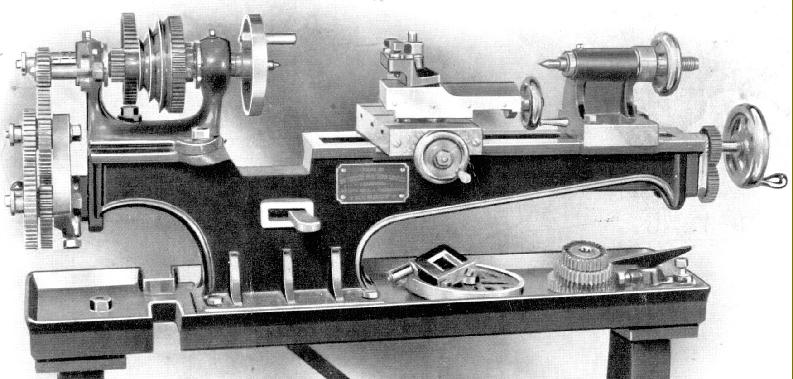

Introduced in 1902 the Drummond flat-bed 3.5" x 16" (and rare 20-inch version) was, in its various guises, to continue in production for almost half a century with the final model, the M-type (introduced in 1921) being assembled (by Myford, from spares), as late as the 1952. Although the early flat-bed lathes are often all referred to as the "B Type" strictly speaking that designation did not apply until the appearance of a much-modified lathe in 1912 - and after the introduction of the Round Bed, in 1908, a lathe Drummond called the "A Type". However, the maker's contemporary catalogue description, "31/2-inch Centre Back Geared, Self-acting Sliding, Boring, and Screwcutting Lathe" whilst accurate, is a little long for handy use - so for the purpose of easy reference to the very first flat-bed lathes we might call them "Mk. 1 Pre B-Type Flat Beds".

In sacrificing some rigidity in favour of stylistic adornment the lathe followed late 19th century practice (note the shape of the bed and the graceful sweep of the headstock casting) but the design was sound and the features introduced during the first few years of production - a compound slide rest, adjustable headstock bearings, dog clutch on the leadscrew, backgear, set-over tailstock and swing headstock - were guaranteed to appeal to the market. A wide range of accessories (milling slides, grinding attachments, wood-turning rests, overhead-drive system, etc.), was also made available. The spindle was driven by a round leather "rope" (sometimes called a "gut-drive") that passed over the chip tray in the two highest speeds, but though slots in its edge on the lowest, to a treadle-operated flywheel mounted on the left-hand leg of the cast-iron stand; the latter seem to have had legs built in at least three different heights, according to the examples that have passed through the writer's hands over the years.

Introduced in 1908 the Round-bed Drummond was intended to sell at the "bottom-end" of the market and had, by the end of its production in 1939, proved to be a very popular and successful machine, especially amongst amateur turners. However, this was not the cheapest Drummond ever offered, that honour belongs to the "Little Goliath" - which was both the least expensive and smallest - with its compound slide rest ways constructed from pairs of steel bar, a design also used by the Austrian Emco company during the early 1950s for their mass-production SL1000/DB200. Several larger lathes were also made, including the interesting Drummond-Barreto, but the range of heavy lathes was very restricted when compared with the wide variety offered by contemporary firms such as Lang, Butler, Swift, Smith & Coventry, Dean, Smith & Grace, Binns & Berry, Willson and Denham. Fortunately, despite their initially limited product range, Drummond managed to sell many examples to the British armed services and company records have survived that make it possible to identify even which particular warship a Drummond lathe was allocated to. A surprising number of these older lathes are still about in original condition (even with their treadle gear) and make both a useful and interesting addition to any enthusiast's workshop.

In October 1953 the Drummond Company was bought by Asquiths, another well-known English machine-tool concern, who wanted to expand their involvement in multi-tool, copying lathes and gear-hobbing machinery. Staveley Industries, who had used capital acquired during the 1950s as compensation for the post WW2 nationalisation program to buy a range of British machine-tool companies, acquired control of Asquiths in 1966. Even though the original Drummond-designed multi-tool lathes, the Maximatic and Maxirapid, together with a gear shaper, the Maxicut, were made until about 1970 the writing was on the wall and, by 1981, Staveley (whose technical knowledge and marketing abilities were regarded with derision throughout the industry) had asset stripped many of its firms, closed their factories and sold off the land.

Although outside the remit of this article, the range of Drummond's post WW2 industrial machines consisted of various models the origins of which can be traced back to the introduction in the mid 1930s of an "Electraulic" broaching machine the Model WA (discontinued in 1948) and the Maxicut No. 00, Maxicut No. 0, Maxicut (no number), Maxicut No. 1 and Maxicut No. 2 production lathes. These original machines continued in various forms, with gradual deletions to the range until the last of the libe, a Maxicut No. 1 Type Y, was made in 1951.

A more complex multi-tool lathe, the Maximatic, and its smaller companion, the Maximinor, were introduced in 1946 and continued in production until 1964. A copy-turning lathe, the Maxicut Electronic (with electronic controls) was first shown in 1955, and made until 1961 whilst another multi-tool lathe, the Maximajor, had a three year run from 1955 to 1958. The last lathes to be developed were the Maxirapid multi-tool and Maxipilot copying lathes: these were manufactured from 1958 until at least 1970 in the case of the former, and 1964 in the case of the latter - the year the Hoblique hobbing machine was introduced. Besides lathes Drummonds also produced a very popular range of gear shapers the 2A, 2B, 2C, 3A and 4A - the Maxicut 2A being introduced in 1946 and built alongside the larger 4A (introduced in 1949) until after 1970. Another type of gear shaper, the FD, was also produced in several models and ran from 1946 to 1952. The Drummond gear shapers are still produced today, in an improved form, and a full back-up and spares service is available for older models.

Continued below:

|

|