fotogalerie

Frézovací vřeteník. Ocelové kuželové osazení aretované maticí se třemi červíky za vřetenem. Upnutí viz nákres u AZ.

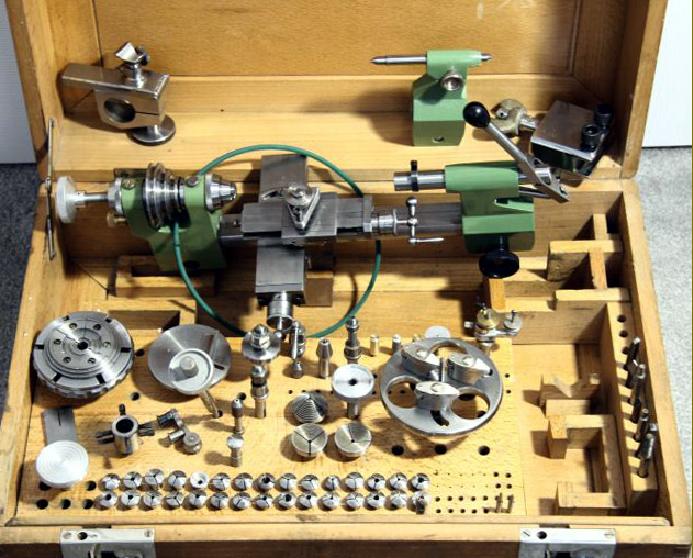

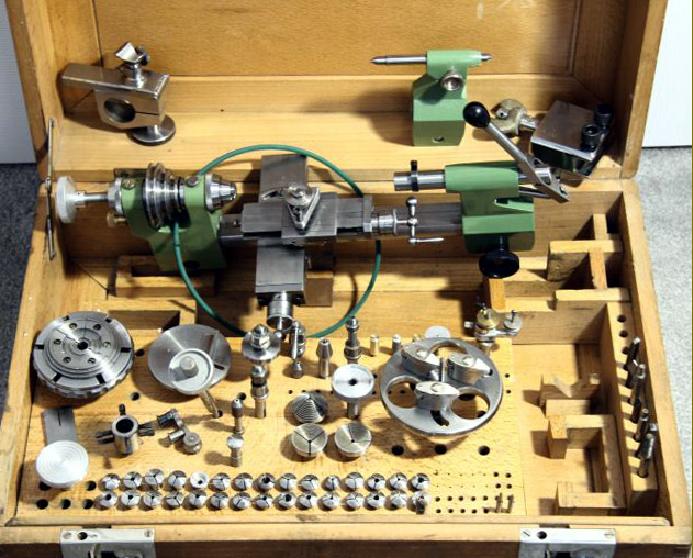

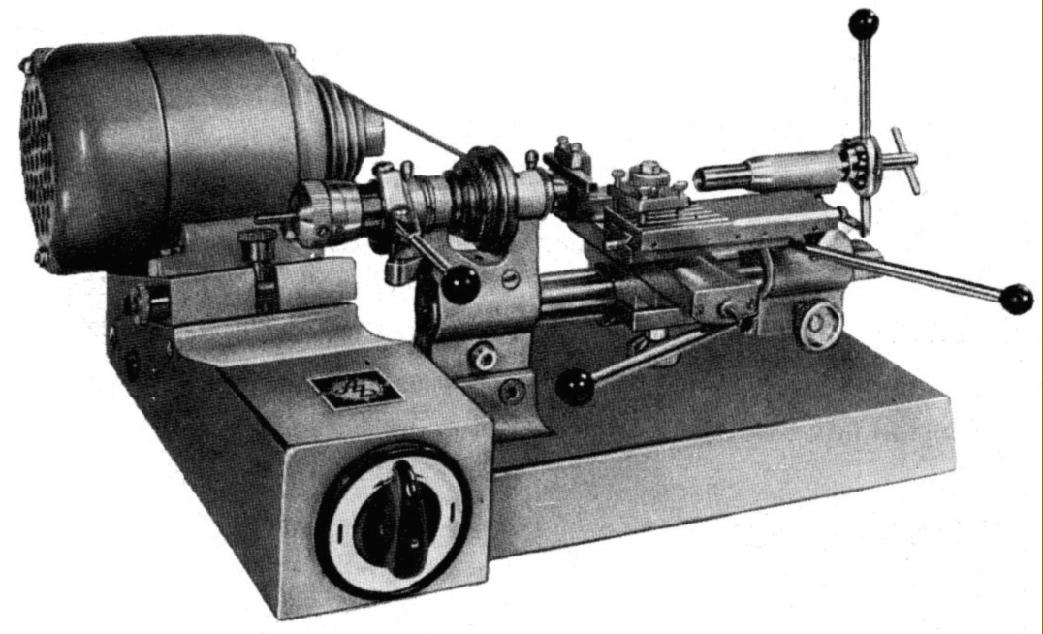

Takový vymazlený hodinářský soustruh od soudruhů z NDR. Východní větev G.Boley.

Jeden poválečný model měl samocentrující broušený ocelový kónus nasazený na ose, na té citlivější straně u otvoru pro kleštiny.

Na straně u držadla upínací tyče byl uprostřed levého vnějšího ramene zářez pro dvě matice nastavující radiální vůli proříznutého bronzového futra.

Od tohoto řešení se později ustoupilo pro výrobní náročnost a ladilo se každé pouzdro svojí jednou převlečnou maticí zvlášť.

Axiální vůle byla odedávna stavěna bronzovou proříznutou maticí s jemným závitem, zajištěnou tangenciálním šroubkem napříč štěrbinou zářezu.

Takový popis může do světa, až když ho pochopí sám autor po přečtení s odstupem několika let.

Novější hranatější, robustnější, velké kolo vřeteníku s integrovanou deličkou zleva, z vnejšku,

jehla deličky procházela tělem uložení Vřeteníku.

Mosazné konusy lze stahovat posuvem vlevo, vždy dvojicí matek.

od kleštiny nasazena pouze distancni podložka s vnejším závitem pro prachovku na dvou šteftech.

Starší oblé modely více ceněny.

Motor se šesti kabely, asi stejnosměrný. Předřadný potenciometr 250 Ohm/100 W.

Čtyřiceti dílkový nonius s 10 závity na 8 milimetrech a s nulovacím kroužkem.

Největší žijící machr na AZ soustruhy je pan Znamenáček.

.

Andrä & Zwingenberger

A maker of watch and clockmakers' equipment based in the communist German Democratic Republic (GDR-DDR) Andrä &

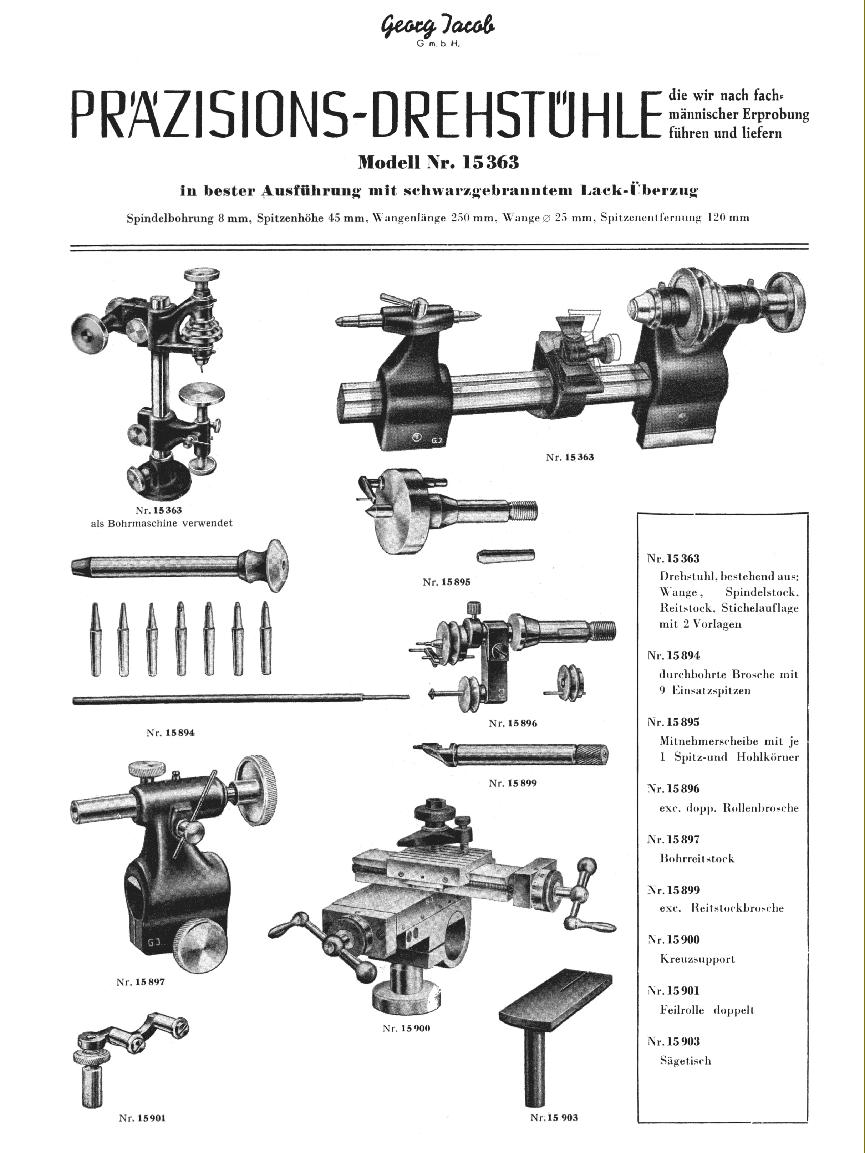

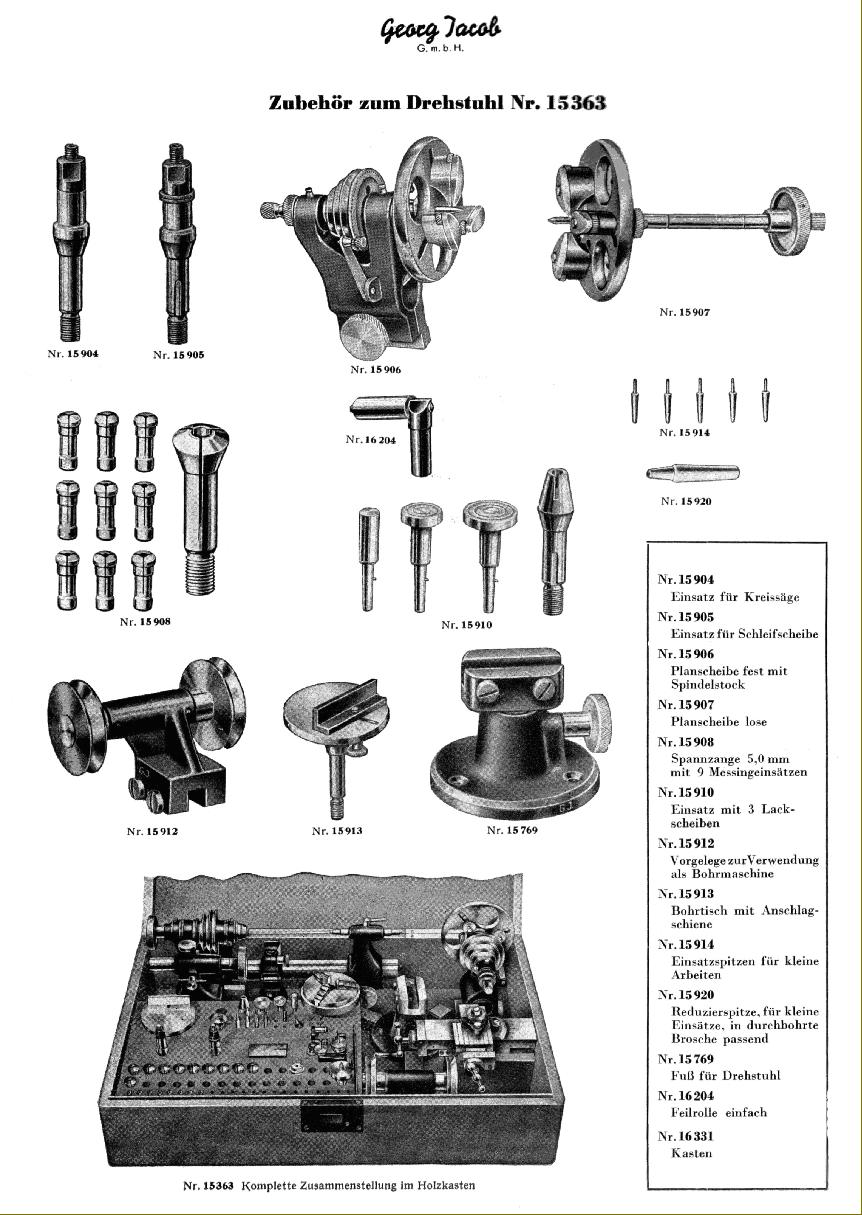

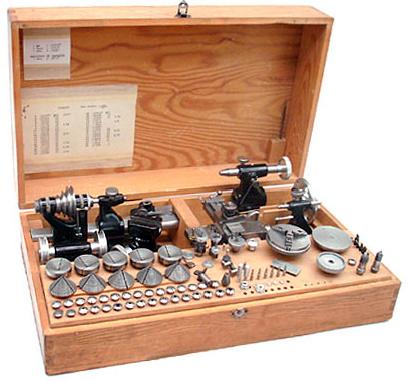

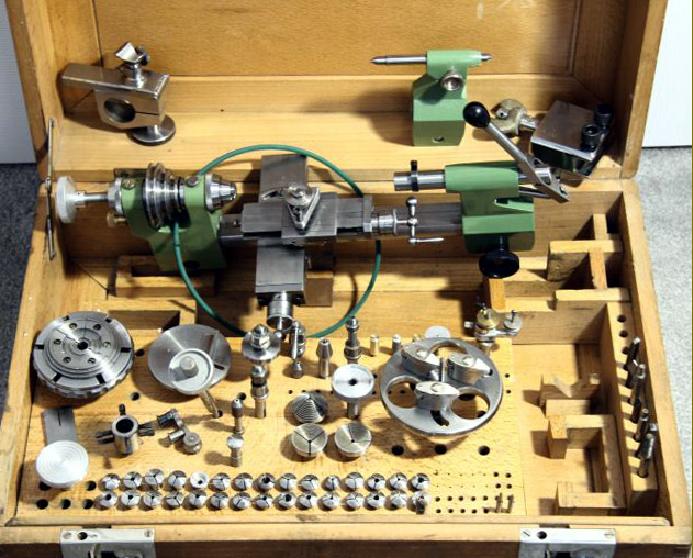

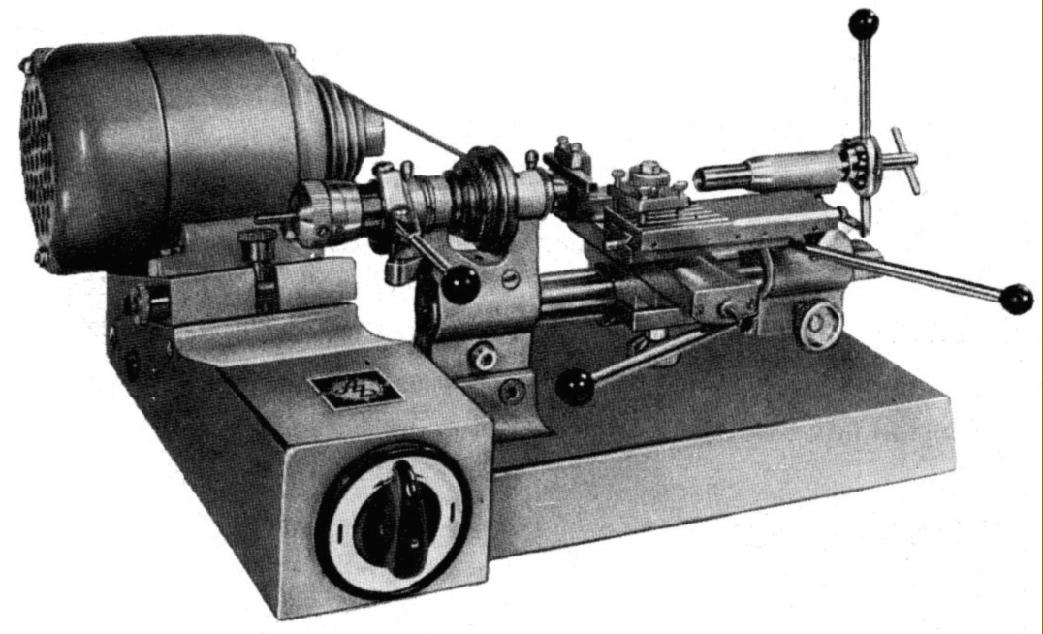

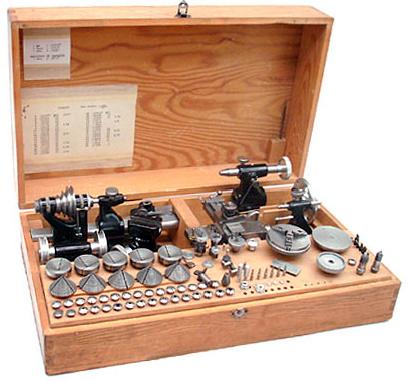

Zwingenberger were best known in the west for their late-model Boley-like 8 mm "WW" type lathes. These were manufactured from the 1950s until the late 1960s (or even 1970s) and were of heavier-than-normal construction with a 25 mm diameter bed - as distinct from the 19 or 20 mm used by G.Boley - and usually offered as a complete, boxed kit at a bargain price - the aim being to acquire Western currency at almost any cost. Unlike most other watchmaker's lathes paint (beautifully applied) was used on headstock and tailstock - again mimicking the last of the Boley WW lathes made during the 1950s.

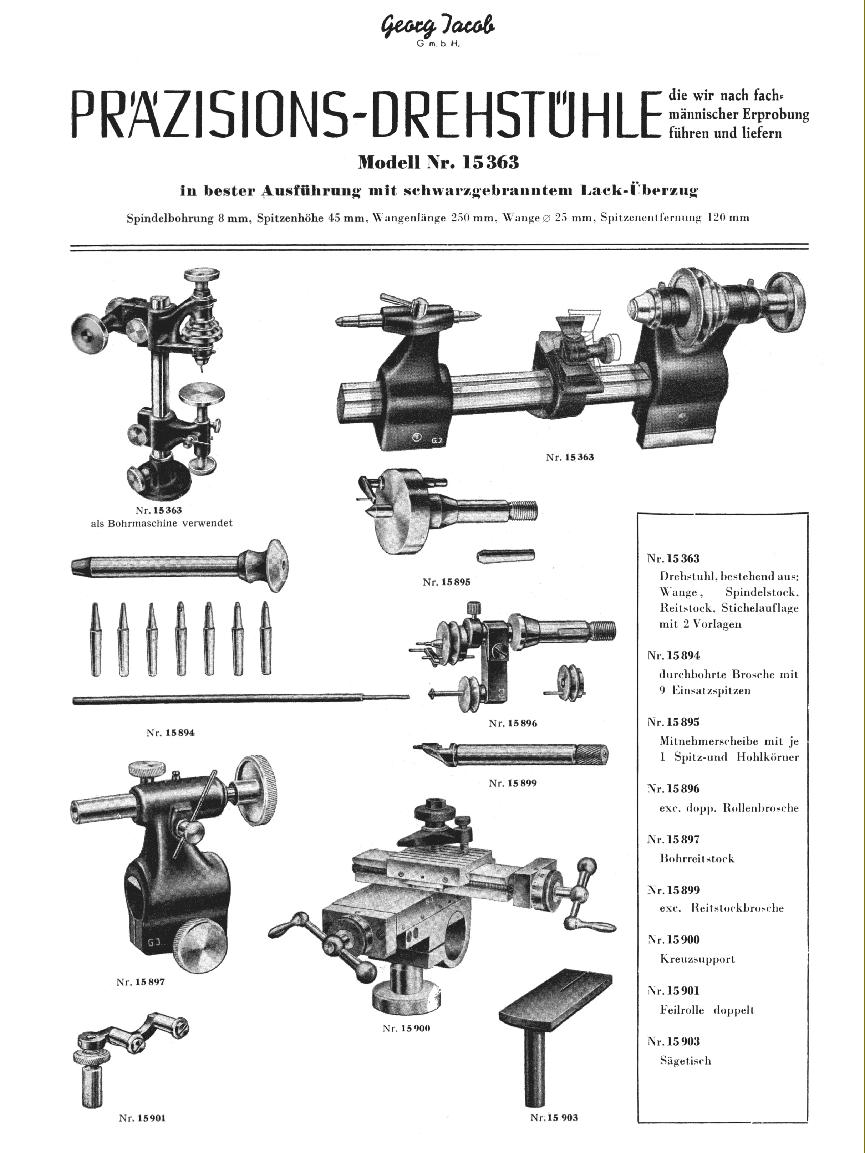

The lathe was marketed world-wide, with the East German dealers Georg Jacob perhaps responsible for stamping the end of the bed G. Boley - though with a lack of finesse, the heavy punching and thicker letters too close together betraying the origins of the lathe.

Some recent observations by the owner of a used example include:

…..the solid white oak varnished case has finger (box) joints and panel construction for the top and bottom with very interesting pivoting latches that are flush with the front side when closed - so allowing a very safe, positive locking.

With a centre height of 45 mm and 130 mm between centres, the lathe is a little short of 260 mm long . The bed is 25 mm diameter (it actually measures 24.99 mm) and is mounted on a nickel-plated foot with two 8 mm hex cap screws to secure the headstock and a 12.6 mm bolt and wing nut to clamp it to a bench. The bed is made from a solid bar of polished steel with a flat on top and grooved along the full length of the center line. It is stamped "G. Boley Germany" at one end while the other has a centre hole - with another hole lower down for an unknown use. The same name stamp can also be found on the base of the hand- rest base and underneath the saw table.

With an immaculate green paint finish the lathe uses a cast-iron headstock with an 8 mm bore spindle to take 8 mm collets secured with a steel draw tube having an aluminum handle. On the outer flange of the 3-step drive pulley is a circle of 60 division holes (with four larger holes evenly spaced every 15 to index a square) and indexed with the usual spring detent pin. The spindle bearings are plain bronze with ring-type adjusting nuts.

Two different cast-iron tailstocks, with black aluminum tightening nuts, are included with the lathe. The ordinary fixed version has the usual double-ended spindle, with male and female centers, whilst the drilling tailstock operates smoothly, has its own draw-in collet closer, an absolute maximum travel of 40 mm and a V-groove on the underside to prevent rotation. The adjustable (blackened steel) ring with screw lock located on the left side - though how this could be effective is difficult to see - a better position would be on the right hand side, between the tailstock body and the handle to limit travel.

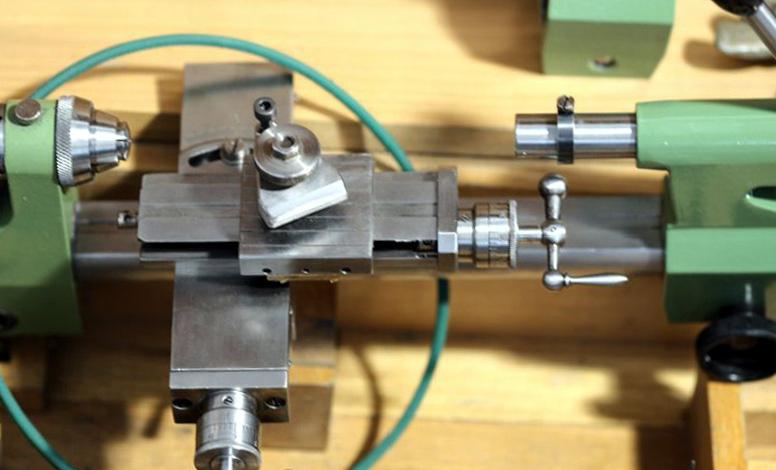

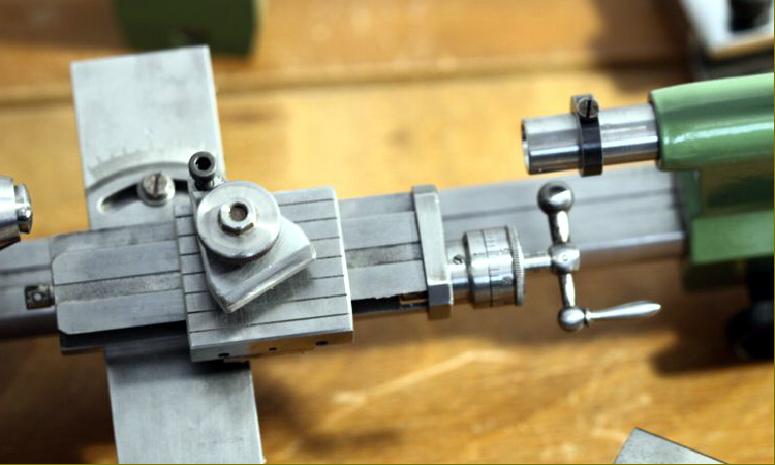

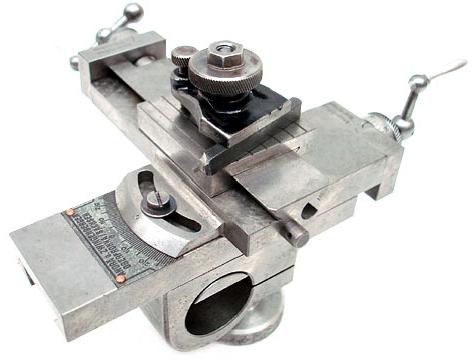

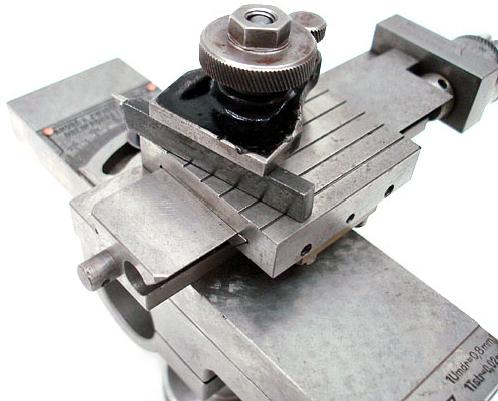

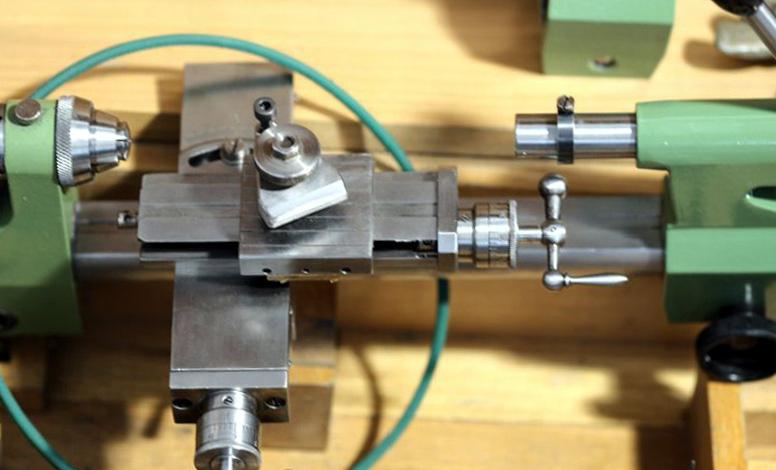

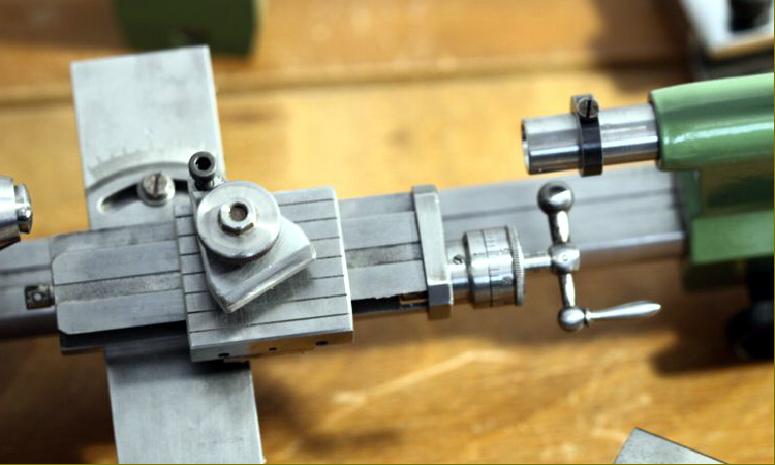

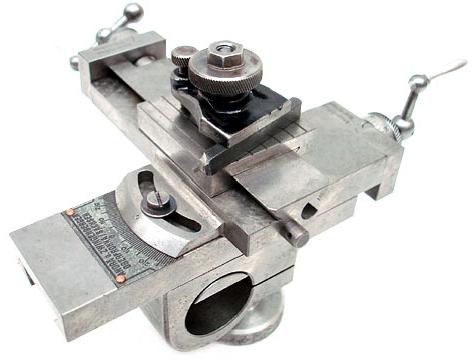

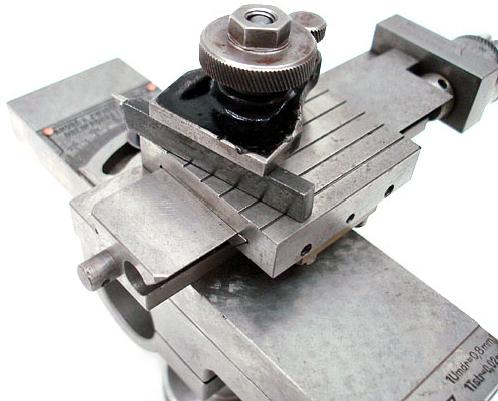

With traditional dovetail construction and gib-strip adjustment - just 2 screws for the top slide but 6 for the cross slide - the compound slide rest is well made and has a smooth, even silky, feel. The 0.8 mm pitch feed-screws run through bronze nuts and are equipped with 0-40 divisions (= 0.02 mm per division) and neat, zeroing micrometer dials with friction locking. Useful travel of the top slide is estimated at 50 mm and 35 mm for the cross slide.

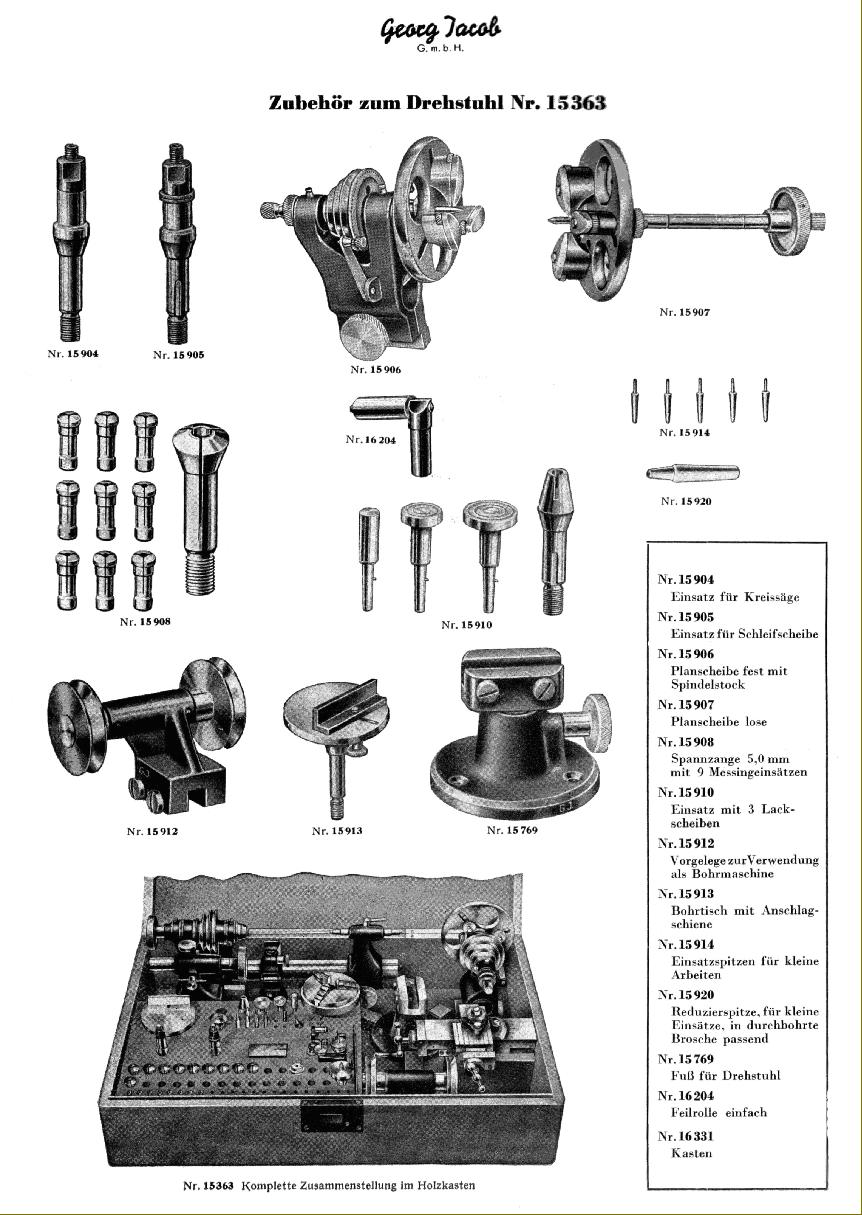

Included in the accessory kit are a number of useful items - through the tip-over T-rest does not match its base with any great accuracy and the two parts may well be of different origin as the filing roller-rest and saw table (20 by 40 mm) do not fit the hole - being larger by some 0.275" on the diameter of their support bars. Of 59 mm diameter the plain faceplate has one axial slot and adjustable angle plate, 44 mm long by 10 mm by 10 mm. The 85 mm diameter three-jaw faceplate is supplied with its own draw bar with a spring-center finder. the universal 68 mm diameter self-centering 3-jaw chuck can grip pieces internally and externally. The pivoting attachment appears to be of good quality as does a tailstock broche - the same as Nr. 15896 and 15 899 Georg Jacob model respectively. A number of collets, ring chucks, wax chucks and arbors complete the set.

If any reader can offer further insights into Andrä & Zwingenberger and their products the writer would be pleased to hear from them.

|

|

|

|

|

|

|

|

|

|

|

|

Note quite what it seems….

Although very late model Boley WW type watchmakers lathes had painted headstocks and tailstocks the example shown here - though clearly stamped Boley on the end of the bed - has a bed diameter of 25mm - whilst all known genuine Boley-made versions are 19 to 20mm.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1957 Catalogue from Georg Jacob

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

An all-lever-feed production version of the East German "Model 15363" dating from 1976 and arranged on a self-contained motor-drive and base unit.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The screw-feed compound slide rest followed the rest of the lathe in being of heavy construction - with generous amounts of slide travel - and 40 divisions on the metric micrometer dials.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parallel lines engraved on the top-slide tool clamping area are an immediate identification point

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The lack of finesse in the "G.Boley" stamp - heavy punching and the thicker letters too close together - betrays the origins of the lathe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|