"Standard Adept" Photographs "Super Adept" Photographs Maker's Letter Adept Shapers

Australian T.N.C. Adept Specialist Adept Pages Buying a New Adept

Manufactured from as early as 1930 until the early 1960s the tiny "Adept" and "Super-Adept" lathes and shapers and were made in Sellers Street, off Abbeydale Road, Sheffield, England by a branch of the Portass family, F. W. Portass. Although, by the most generous stretch of the imagination, these lathes cannot be called other than crude, they did provided the impecunious enthusiast with a way of getting his (and occasionally her) hands on very a hard-to-come-by product. Today they are sought-after items and using one provides a fascinating insight into times that were so much harder than our own.

The very first Portass lathes, which date from the early 1920s (and possibly before) were badged as being made in the west of Sheffield by "The Heeley Motor Manufacturing Company" then the: "The Portass Lathe and Machine Tool Company". Although Sheffield's main heavy industries, and the larger-volume steel plants of Rotherham, lay to the east (and down-wind of the better-class housing), there had been a long tradition of both large and small-scale engineering in the western Sheffield valleys originally using water power from the Sheaf, Porter, Loxley steams.

The original Portass company, founded in 1889 by Charles Portass, was concerned with building and constructional engineering but by the outbreak of the First World War (1914--1918) had evolved to the extent that it was able to take on a variety of government work. Projects given to the company including the usual munitions work and more interesting tasks involving the manufacture of aircraft components such as landing gear parts for Avro, Bristol and Nieuport fighters, seaplane floats for Blackburn and Fairey, tail units for Avro and De Haviland and even the building of a complete batch of 50 Sopwith Snipe monoplanes. In the 1920s, and by now trading under the "Heeley Motor Manufacturing" name, the company turned its hand to building bodies for the car, lorry, ambulance and bus markets but, as these had become an increasingly "in-house" activity for manufactures, Portass diverted into the manufacture of small machine tools for the hobby and light-industrial market.

Following the founder's death in 1924 (and almost certainly at the point where diversification into machine tools was taking place), the business was split between his sons Fred and Stanley. Fred ran "F. W. Portass", a company that concentrated exclusively on tiny lathes and shapers badged "Adept", whilst Stanley made only larger machines with his business eventually becoming, around 1953 (or earlier), "Charles Portass & Son". Stanley was based by the river Sheaf in the "Buttermere Works" (the building still stands, in Buttermere Road, off Abbeydale Road, near Millhouses, whilst F.W.Portass was located in Sellers Street - again off Abbeydale Road, but a mile closer to the city centre. Letters survive showing how, unsurprisingly, the two companies were frequently mistaken for each other with mail having to be redirected. At one time Sheffield, famous for its high-quality specialised steels and the many industries closely associated with them - munitions, general engineering, forgings of all kinds, cutlery, machine knives, springs and numerous hand and edge-tool makers - must have been something of a centre for small-lathe production for, besides the Portass concerns, Flexispeed, Faircut, Kay and (possibly) Graves were being made there as well. Later the tradition was carried on by the well-known woodworking-tool manufacturer Sorby who during the 1990s produced a top-quality wood-turning lathe (and a range of other wood-turning related products) in premises not 100 yards from what had been Stanley's factory.

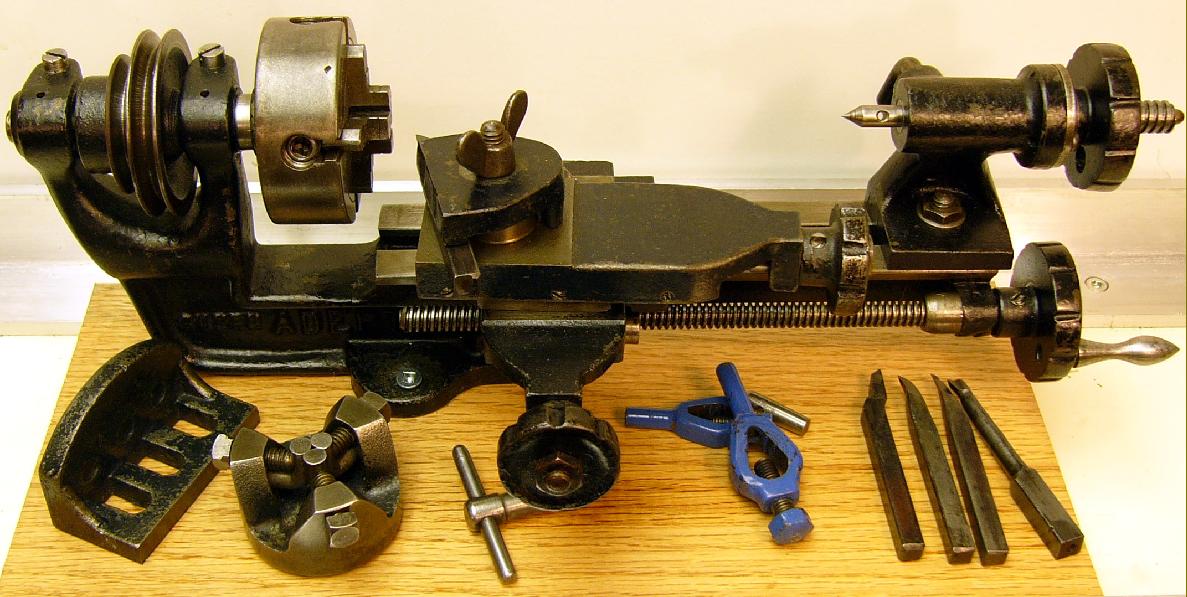

The announcement of the ordinary adept has been traced to 1931 and of the much improved Super Adept to August 1933 - when the latter was displayed at the "Model Engineer" Exhibition on the stand of the then well-known tool dealer "Bond's o' Euston Road". Fitted with a bolt-on compound slide the ordinary version of the Adept used the top slide to take a cut which, like watch and clockmakers' lathes, had a slide of sufficient length to cover a good proportion of the available between-capacity distance. The "Super-Adept" (which, judging by the numbers encountered, must have been the better-seller of the two) was fitted with a sliding carriage driven by hand from a properly "waisted" handle fitted to the tailstock end of an overhung Acme-form, left-hand 12 t.p.i. leadscrew. The headstock was fitted with simple, bronze bushes in split housings that were adjustable over a small range; the spindle carried a 3/8" British Standard Fine (BSF) thread and a tiny taper, probably contrived as a non-standard type in the works, and yet which is not consistent and appears to vary a little either side of a No. 0 Morse according to which machine is measured The saddle was fitted with an adjustable gib strip at the rear, not the best place to introduce a flexible piece of strip steel to absorb the tool thrust but, even if it had been correctly placed at the front, leaving the rear of the casting to bear directly against the bed, it would probably have made little difference considering the low forces the machine was able to generate. The tailstock on early versions had a simple push-and-lock barrel but the inadequacies of this quickly became apparent and the makers introduced a properly designed unit with the choice of screw or lever-feed operation. Both versions of the lathe were identical dimensionally, lightly built ands just 13.75 inches long and around 6.5 lbs in weight; the centre height was 15/8" inches and the capacity between centres 6 inches; the gap, standard on both models, admitted a piece of material 4.25 inches in diameter. A small 3-speed bench-mounted countershaft was offered by the makers (though most of the impecunious enthusiasts who bought the lathe ignored it) or, at even greater expense, by a two-speed human-powered "foot-motor" and flywheel assembly.

Although inexpensive, lacking in quality control and obviously built down to a strict price (there was no attempt made to smooth out surface imperfections in the castings, or even machine the base of the foot) the black-enameled and sometimes blue-finished "Super" models were still capable, in the right hands, of performing some remarkable tasks. Britain's A.R. Walkley, who modeled tiny electric locomotives in 1 mm =1 foot (1:305 scale) used an Adept lathe to make his own miniature motors and reported that: "parts including a 0.25"-diameter cast iron armature were ….. produced on the lathe. This says much for the Adept when one mentions that everything came out true even to the boring of the miniature armature - the sort of job that many more expensive lathes are not always able to do well."

A well-made 4-jaw independent chuck with a threaded body and stamped "ADEPT" was available as an extra, but its cost, at one pound, twelve shillings and sixpence, was 33% of that of the lathe; what everybody would have liked, a miniature, 3-jaw scroll-operated self-centering chuck, was unavailable - it obviously being too difficult to construct such an accurate item and sell it for a reasonable price. Instead, a crude non-self-centering "dog" 3-jaw was offered - a chuck that was inaccurate, frustrating to use and with a poor grip - though skilled users could still make it perform miracles.

It is possible that a proper screwcutting version of the adept was made by the works; pictures obtained show a modified headstock casting with a large plate bolted to the front carrying both a leadscrew bearing and a tumble-reverse mechanism. Unfortunately it is not possible at this stage to say with certainty that this was the case, for so many craftsmen in Sheffield would have been perfectly capable of undertaking such a modification, even in a very modestly-equipped workshop.

A range of small hand-operated shapers and a tiny horizontal miller was also offered under the Adept name and proved very popular (a delivery time of twelve months was quoted in the late 1940s for the lathes) and are increasingly sought after today by more experienced model and experimental engineers who relish both the tremendous potential they have to solve machining problems - and the fun to be had from using a miniature version of a "real" machine tool.

An exact copy of the Super Adept (and possibly the ordinary version as well) was sold in Australia as the T.N.C. Whether the machine was exported with T.N.C. badges, or manufactured in Australia, is not known and if any reader has copies of T.N.C. advertising literature the writer would be pleased to hear from them.

F. W. Portass was not the only maker of miniature lathes in Sheffield; the Flexispeed was also manufactured there, with works in South Lane, some half a mile nearer to the city center than those occupied by Adept. Unfortunately Adept failed to developed their lathe to keep up with the ever-increasing demands of now more affluent modelller and by the early 1960s was gone. Flexispeed however, with a keener eye on the market managed to continue their lathes being steadily developed with the addition of backgear, power feeds and increased capacity - and even when the original company failed the design had reached such an advanced stage that it was taken up in turn by various concerns and marketed as the Meteor, Hector, Norfolk, Simat 101, Perris and finally as the Cowells--with version of the latter still being built today. A comparison of the Adept with some other simple and inexpensive miniature lathes (both contemporary and later) makes an interesting study.. - AM, Baby Grand, CAV, Clisby, David, Dignus, Edwards, ManSon, Flexispeed, Exclet, Goodell-Pratt, Grindturn (Haighton Cadet), Guilder, Perris, Cowells, Centrix Micro, Jason, Portass Baby, Little Goliath, Rollo Elf, Taig and Peatol, Unimat, Winkle (Cincinnati Mechanic Maker) and Wizard.

More on the Adept here by an experience Canadian collector and restorer, Andrew Webster.

Tony Griffiths

|

|

|

The ordinary "Adept" version of the lathe was fitted with a bolt-on compound slide rest located in a slot machined down the centre of the bed (the edges were left unmachined). The longitudinal cut was taken, as usual on this type of arrangement, by the top slide and its length was accordingly limited. This lathe also has the maker's hand-turning rest fitted to the right of the compound-slide assembly. More photographs of the standard Adept can be seen here. |

|

"Standard Adept" Photographs "Super Adept" Photographs Maker's Letter Adept Shapers Australian T.N.C. Adept Specialist Adept Pages Buying a New Adept |

||